UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

(Mark One)

|

☒ |

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the Fiscal Year Ended December 31, 2017

OR

|

☐ |

TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the Transition Period From to

Commission file number: 001-36309

INOGEN, INC.

(Exact name of registrant as specified in its charter)

|

Delaware |

|

33-0989359 |

|

(State or other jurisdiction of incorporation or organization) |

|

(I.R.S. Employer Identification No.) |

|

326 Bollay Drive Goleta, California |

|

93117 |

|

(Address of principal executive offices) |

|

(Zip Code) |

(805) 562-0500

(Registrant’s telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

|

Title of each class |

|

Name of each exchange on which registered |

|

Common Stock, $0.001 par value |

|

The NASDAQ Stock Market LLC (NASDAQ Global Select Market) |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ☒ No ☐

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ☐ No ☒

Indicate by check mark whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the Registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ☒ No ☐

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ☒ No ☐

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§229.405 of this chapter) is not contained herein, and will not be contained, to the best of the Registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ☒

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, smaller reporting company, or an emerging growth company. See the definitions of “large accelerated filer,” “accelerated filer,” “smaller reporting company,” and “emerging growth company” in Rule 12b-2 of the Exchange Act.

|

Large accelerated filer |

|

☒ |

|

Accelerated filer |

|

☐ |

|

|

|

|

|

|||

|

Non-accelerated filer |

|

☐ (Do not check if a smaller reporting company) |

|

Smaller reporting company |

|

☐ |

|

|

|

|

|

|

|

|

|

Emerging growth company |

|

☐ |

|

|

|

|

If an emerging growth company, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 13(a) of the Exchange Act.

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes ☐ No ☒

The aggregate market value of the voting and non-voting stock held by non-affiliates of the Registrant, based on the closing sale price of the Registrant’s common stock on the last business day of its most recently completed second fiscal quarter, as reported on The NASDAQ Global Select Market, was approximately $1.2 billion. Shares of common stock held by each executive officer and director and by each other person who may be deemed to be an affiliate of the Registrant, have been excluded from this computation. The determination of affiliate status for this purpose is not necessarily a conclusive determination for other purposes.

As of February 23, 2018, the Registrant had 21,095,176 shares of common stock, par value $0.001, outstanding.

DOCUMENTS INCORPORATED BY REFERENCE

The information called for by Part III of this Annual Report on Form 10-K will be included to the extent stated herein in an amendment to this Form 10-K or incorporated by reference from the Registrant’s definitive Proxy Statement relating to its 2018 Annual Meeting of Stockholders.

|

|

|

|

|

Page |

|

Part I |

|

|

||

|

Item 1. |

|

|

2 |

|

|

Item 1A. |

|

|

23 |

|

|

Item 1B. |

|

|

52 |

|

|

Item 2. |

|

|

52 |

|

|

Item 3. |

|

|

52 |

|

|

Item 4. |

|

|

53 |

|

|

|

|

|

|

|

|

Part II |

|

|

||

|

Item 5. |

|

|

54 |

|

|

Item 6. |

|

|

56 |

|

|

Item 7. |

|

Management’s Discussion and Analysis of Financial Condition and Results of Operations |

|

58 |

|

Item 7A. |

|

|

82 |

|

|

Item 8. |

|

|

83 |

|

|

Item 9. |

|

Changes in and Disagreements with Accountants on Accounting and Financial Disclosure |

|

83 |

|

Item 9A. |

|

|

83 |

|

|

Item 9B. |

|

|

85 |

|

|

|

|

|

||

|

Part III |

|

|

||

|

Item 10. |

|

|

85 |

|

|

Item 11. |

|

|

85 |

|

|

Item 12. |

|

Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters |

|

85 |

|

Item 13. |

|

Certain Relationships and Related Transactions, and Director Independence |

|

85 |

|

Item 14. |

|

|

85 |

|

|

|

|

|

||

|

Part IV |

|

|

||

|

Item 15. |

|

|

86 |

|

i

PART I

Forward-Looking Statements

This Annual Report on Form 10-K contains forward-looking statements within the meaning of Section 27A of the Securities Act of 1933, as amended, or the Securities Act, and Section 21E of the Securities Exchange Act of 1934, as amended, or the Exchange Act, that are based on our management’s beliefs and assumptions and on information currently available to our management. The forward-looking statements are contained principally in the sections entitled “Business,” “Risk Factors,” and “Management’s Discussion and Analysis of Financial Condition and Results of Operations.” Forward-looking statements include, but are not limited to, statements concerning the following:

|

|

• |

information concerning our possible or assumed future cash flow, revenue, sources of revenue and results of operations, operating and other expenses; |

|

|

• |

our assessment of reduced reimbursement rates, the continued impact from competitive bidding, future declines in rental revenue, and future decline in rental patients on service; |

|

|

• |

our expectations regarding regulatory approvals and government and third-party payor coverage and reimbursement; |

|

|

• |

our ability to develop new products, improve our existing products and increase the value of our products; |

|

|

• |

our expectations regarding the timing of new products and product improvement launches; |

|

|

• |

market share expectations, unit sales, business strategies, financing plans, expansion of our business, competitive position, industry environment, potential growth opportunities; |

|

|

• |

our expectations regarding the market size, market growth and the growth potential for our business; |

|

|

• |

our ability to sustain and manage growth, including our ability to develop new products and enter new markets; |

|

|

• |

our expectations regarding the average selling price and manufacturing costs of our products, including our expectations to continue to reduce average unit costs for our systems; |

|

|

• |

our expectation to expand our sales and marketing channels, including through hiring additional sales representatives and expanding our advertising campaigns; |

|

|

• |

our expectations with respect to our European and U.S. facilities and our expectations with respect to our contract manufacturer in Europe; |

|

|

• |

our ability to successfully acquire and integrate companies and assets and the anticipated benefits from our acquisition of MedSupport Systems B.V. (MedSupport); |

|

|

• |

our expectations regarding excess tax benefits from stock-based compensation; |

|

|

• |

our assessments and estimates of our effective tax rate; |

|

|

• |

our internal control environment; |

|

|

• |

the effects of seasonal trends on our results of operations and estimated hiring plans; |

|

|

• |

our expectation that our existing capital resources and the cash to be generated from expected product sales and rentals will be sufficient to meet our projected operating and investing requirements for at least the next twelve months; and |

|

|

• |

the effects of competition. |

Forward-looking statements include statements that are not historical facts and can be identified by terms such as “anticipates,” “believes,” “could,” “seeks,” “estimates,” “expects,” “intends,” “may,” “plans,” “potential,” “predicts,” “projects,” “should,” “will,” “would,” or similar expressions and the negatives of those terms.

Forward-looking statements involve known and unknown risks, uncertainties, and other factors that may cause our actual results, performance, or achievements to be materially different from any future results, performance, or achievements expressed or implied by the forward-looking statements. We discuss these risks in greater detail in Part I, Item 1A, “Risk Factors,” and elsewhere in this Annual Report on Form 10-K. Given these uncertainties, you should not place undue reliance on these forward-looking statements. Moreover, we operate in a very competitive and rapidly changing environment. New risks emerge from time to time. It is not possible for us to predict all risks, nor can we assess the impact of all factors on our business or the extent to which any factor, or

1

combination of factors, may cause actual results to differ materially from those contained in any forward-looking statements we may make. In light of these risks, uncertainties and assumptions, the future events and trends discussed in this Annual Report on Form 10-K may not occur and actual results could differ materially and adversely from those anticipated or implied in the forward-looking statements.

The forward-looking statements made in this Annual Report on Form 10-K relate only to events as of the date on which the statements are made. Except as required by law, we assume no obligation to update these forward-looking statements, or to update the reasons actual results could differ materially from those anticipated in these forward-looking statements, even if new information becomes available in the future.

This Annual Report on Form 10-K also contains estimates, projections and other information concerning our industry, our business, and the markets for certain diseases, including data regarding the estimated size of those markets, and the incidence and prevalence of certain medical conditions. Information that is based on estimates, forecasts, projections, market research or similar methodologies is inherently subject to uncertainties and actual events or circumstances may differ materially from events and circumstances reflected in this information. Unless otherwise expressly stated, we obtained this industry, business, market and other data from reports, research surveys, studies and similar data prepared by market research firms and other third parties, industry, medical and general publications, government data and similar sources.

“Inogen,” “Inogen One,” “Inogen One G2,” “Inogen One G3,” “G4,” “Oxygenation,” “Live Life in Moments, not Minutes,” “Never Run Out of Oxygen,” “Oxygen Therapy on Your Terms,” “Oxygen.Anytime.Anywhere,” “Reclaim Your Independence,” “Intelligent Delivery Technology,” “Inogen At Home,” and the Inogen design are registered trademarks with the United States Patent and Trademark Office of Inogen, Inc. We own trademark registrations for the mark “Inogen” in Australia, Canada, South Korea, Mexico, Europe (European Union registration), and Japan. We own a trademark registration for the mark “イノジェン” in Japan. We own trademark registrations for the mark “Inogen One” in Australia, Canada, China, South Korea, Mexico, and Europe (European Union registration). We own a trademark registration for the mark “Satellite Conserver” in Canada. We own a trademark registration for the mark “Inogen At Home” in Europe (European Union Registration). We own trademark registrations for the mark “G4” in Europe (European Union registration) and the United Kingdom. Other service marks, trademarks, and trade names referred to in this Annual Report on Form 10-K are the property of their respective owners.

In this Annual Report on Form 10-K, “we,” “us” and “our” refer to Inogen, Inc. and its subsidiaries.

General

We were incorporated in Delaware on November 27, 2001. We are a medical technology company that primarily develops, manufactures and markets innovative portable oxygen concentrators used to deliver supplemental long-term oxygen therapy to patients suffering from chronic respiratory conditions. Traditionally, these patients have relied on stationary oxygen concentrator systems for use in the home and oxygen tanks or cylinders for mobile use, which we call the delivery model. The tanks and cylinders must be delivered regularly and have a finite amount of oxygen, which requires patients to plan activities outside of their homes around delivery schedules and a finite oxygen supply. Additionally, patients must attach long, cumbersome tubing to their stationary concentrators simply to enable mobility within their homes. Our proprietary Inogen One® systems concentrate the air around the patient to offer a single source of supplemental oxygen anytime, anywhere with a portable device weighing approximately 2.8, 4.8 or 7.0 pounds with a single battery. Our Inogen One G4®, Inogen One G3® and Inogen One G2® have up to 2.6, 4.7 and 5.0 hours of battery life, respectively, with a single battery and can be plugged into an outlet when at home, in a car, or in a public place with outlets available. Our Inogen One systems reduce the patient’s reliance on stationary concentrators and scheduled deliveries of tanks with a finite supply of oxygen, thereby improving patient quality of life and fostering mobility.

Portable oxygen concentrators represented the fastest-growing segment of the Medicare oxygen therapy market between 2012 and 2016. We estimate based on 2016 Medicare data that the total number of patients using portable oxygen concentrators represents approximately 9.1% of the total addressable oxygen market in the United States, although the Medicare data does not account for private insurance and cash-pay patients in the market. Based on 2016 industry data, we believe we were the leading worldwide manufacturer of portable oxygen concentrators. We believe we are the only manufacturer of portable oxygen concentrators that employs a direct-to-consumer strategy in the United States, meaning we market our products to patients, process their physician paperwork, provide clinical support as needed and bill Medicare or insurance on their behalf. To pursue a direct-to-consumer strategy, our manufacturing competitors would need to meet national accreditation and state-by-state licensing requirements and secure Medicare billing privileges, including Medicare competitive bidding contracts, as well as compete with the home medical equipment providers who many of our manufacturing competitors sell to across their entire homecare businesses.

2

Since adopting our direct-to-consumer strategy in 2009 following our acquisition of Comfort Life Medical Supply, LLC, which had an active Medicare billing number but few other assets and limited business activities, we have directly sold or rented more than 362,000 of our Inogen oxygen concentrators as of December 31, 2017.

We incorporated Inogen Europe Holding B.V., a Dutch limited liability company, on April 13, 2017. We own all outstanding stock of Inogen Europe Holding B.V., which became a wholly owned subsidiary of Inogen, Inc.

Our market

We believe the current total addressable oxygen therapy market in the United States is approximately $3 billion to $4 billion, based on 2016 Medicare data and our estimate of the ratio of the Medicare market to the total market. As of 2016, we estimate that there are 4.5 million patients worldwide who use oxygen therapy, including 2.5 to 3 million patients in the United States, and more than 60% of oxygen therapy patients in the United States are covered by Medicare. The number of oxygen therapy patients in the United States is projected to grow by approximately 7% to 10% per year between 2017 and 2021, which we believe is the result of earlier diagnosis of chronic respiratory conditions, demographic trends and longer durations of long-term oxygen therapy.

Long-term oxygen therapy has been shown to be a cost-efficient and clinically effective means to treat hypoxemia, a condition in which patients have insufficient oxygen in the blood. Hypoxemic patients are unable to convert oxygen found in the air into the bloodstream in an efficient manner, causing organ damage and poor health. Chronic obstructive pulmonary disease, or COPD, is a leading cause of hypoxemia. Approximately 70% of our patient population has been diagnosed with COPD, which we believe is reflective of the long-term oxygen therapy market in general. Industry sources estimate that 24 million people in the United States suffer from COPD, of which one-half are undiagnosed.

According to our analysis of 2016 Medicare data, approximately 70% of U.S. oxygen users require ambulatory oxygen and the remaining 30% are considered stationary, and either require oxygen twenty-four hours a day, seven days a week, or 24/7, but are not ambulatory, or do not require oxygen 24/7 and only need nocturnal oxygen. Clinical data has shown that ambulatory patients that use oxygen 24/7 regardless of whether such patients rely on portable oxygen concentrators or the delivery model, have approximately two times the survival rate and spend at least 60% fewer days annually in the hospital than non-ambulatory 24/7 patients. The cost of one year of oxygen therapy is less than the cost of one day in the hospital. Of the ambulatory patients, we estimate based on 2016 Medicare data that greater than 85% rely upon the delivery model, which has the following disadvantages:

|

|

• |

limited flexibility outside the home, dictated by the finite oxygen supply provided by tanks and cylinders and dependence on delivery schedules; |

|

|

• |

restricted mobility and inconvenience within the home, as patients must attach long, cumbersome tubing to a noisy stationary concentrator to move within their homes; |

|

|

• |

products are not cleared for use on commercial aircraft and cannot plug into a vehicle outlet for extended use; and |

|

|

• |

high costs driven by the infrastructure necessary to establish a geographically diverse distribution network to serve patients locally, as well as personnel, fuel and other costs, which have limited economies of scale and generally increase over time. |

Portable oxygen concentrators were developed in response to many of the limitations associated with traditional oxygen therapy. Portable oxygen concentrators are designed to offer a self-replenishing, unlimited supply of oxygen that is concentrated from the surrounding air and to operate without the need for oxygen tanks or regular oxygen deliveries, enhancing patient freedom and independence. Additionally, because portable oxygen concentrators do not require the physical infrastructure and service intensity of the delivery model, we believe portable oxygen concentrators can provide long-term oxygen therapy with a lower cost structure. Despite the ability of portable oxygen concentrators to address many of the shortcomings of traditional oxygen therapy, we estimate based on 2016 Medicare data that the total number of patients on portable oxygen concentrators represents approximately 9.1% of the total addressable oxygen market in the United States, although the Medicare data does not account for private insurance and cash-pay patients in the market. We believe the following have hindered the market acceptance of portable oxygen concentrators:

|

|

• |

to obtain portable oxygen concentrators, patients are dependent on home medical equipment providers, which have made significant investments in the physical distribution infrastructure to support the delivery model and which we believe are therefore disincentivized to encourage adoption of portable oxygen concentrators; |

|

|

• |

lack of patient and physician awareness of the existence and benefits of portable oxygen concentrators as an oxygen solution instead of the traditional delivery model; |

3

|

|

• |

constrained manufacturing costs of conventional portable oxygen concentrators, driven by home medical equipment provider preference for products that have lower upfront equipment cost; and |

|

|

• |

limitations of conventional portable oxygen concentrators, including bulkiness, poor reliability and lack of suitability beyond intermittent or travel use. |

Our solution

Our Inogen One systems provide patients who require long-term oxygen therapy with a reliable, lightweight single solution product that we believe improves quality-of-life, fosters mobility and eliminates dependence on both oxygen tanks and cylinders as well as stationary concentrators. We believe our direct-to-consumer strategy increases our ability to effectively develop, design and market our Inogen One solutions, as it allows us to:

|

|

• |

drive patient awareness of our portable oxygen concentrators through direct marketing, thereby fueling our direct-to-consumer sales channel and creating pull through for our business-to-business channel. Other manufacturers solely rely upon selling to homecare businesses, many of whom are incentivized to continue to service oxygen patients through the delivery model; |

|

|

• |

capture the manufacturer and home medical equipment provider margins on a portion of our revenue, allowing us to focus on the total cost of the solution and to invest in the development of product features instead of being constrained by the price required to attract representation from a distribution channel. For example, we have invested in features that improve patient satisfaction, product durability, reliability and longevity, which increase the cost of our hardware, but reduce the total cost of our solution by reducing our maintenance and repair cost; and |

|

|

• |

access and utilize direct patient feedback in our research and development efforts, allowing us to innovate based on this feedback and stay at the forefront of patient preference. For example, certain of the specifications of the Inogen One G4 and its accessories were created based on direct patient feedback. |

We believe the combination of our direct-to-consumer strategy with our singular focus on designing and developing oxygen concentrator technology has created the best-in-class portfolio of portable oxygen concentrators. Our three current portable product offerings, the Inogen One G4, Inogen One G3 and Inogen One G2, at approximately 2.8, 4.8 and 7.0 pounds with a single battery, respectively, are among the lightest portable oxygen concentrators on the market and offer among the highest oxygen flow capacity per pound. We believe our Inogen One solutions offer the following benefits:

|

|

• |

Single solution for home, ambulatory, travel (including on commercial aircraft) and nocturnal treatment. We believe our Inogen One solutions are the only portable oxygen concentrators marketed as a single solution, by which we mean a patient can use our Inogen One systems as their only supplemental oxygen source with no need to also use a stationary concentrator regularly. Our compressors are specifically designed to enable our patients to run our portable oxygen concentrators 24/7, whether powered by battery or plugged into an outlet at home or in a car while the battery is recharging. |

|

|

• |

Reliability. We have prioritized product performance and reliability in each of our design projects and continuous improvement efforts. For example, beginning with the Inogen One G2, we have designed and manufactured our own compressors to ensure long life and high reliability. We have also continually improved compressor component designs and manufacturing processes throughout the product life cycle to capitalize on our integrated design and manufacturing team approach. Reliability is not only critical to patient satisfaction, but also to our cost management initiative, as our minimal physical infrastructure makes product exchanges more costly to us than providers with greater local physical infrastructure. |

|

|

• |

Effective for nocturnal use. Our Intelligent Delivery Technology enables our portable oxygen concentrators to provide consistent levels of oxygen during sleep despite decreased respiratory rates. As a result, patients can rely on our Inogen One portable oxygen concentrators overnight while sleeping. |

|

|

• |

Unparalleled flow capacity. Our 2.8 pound Inogen One G4 has higher flow capacity than other sub-3 pound portable oxygen concentrators, our Inogen One G3 has higher flow capacity than other sub-5 pound portable oxygen concentrators, and our 7.0 pound Inogen One G2 has higher flow capacity than other sub-10 pound portable oxygen concentrators. |

|

|

• |

User friendly features. Our systems are designed with multiple user-friendly features, including long battery life and low noise levels in their respective weight categories. |

4

Our Inogen One systems and Inogen At Home system

We market our current portable product offerings, the Inogen One G4, the Inogen One G3 and the Inogen One G2, as single solutions for oxygen therapy. This means our solutions can operate on a 24/7 basis for at least 60 months without a stationary concentrator. We believe the technology in our Inogen One systems is effective for nocturnal use. Our Inogen One G4, Inogen One G3 and Inogen One G2 are sub-3, sub-5 and sub-10 pound portable oxygen concentrators, respectively, that can operate reliably and cost-effectively over the long period of time needed to service oxygen therapy patients without supplemental use of a stationary concentrator or a replacement portable oxygen concentrator. The following table summarizes our key product features:

|

|

|

Key Product Specifications |

|

|||||||

|

|

|

Inogen One G4 |

|

Inogen One G3 |

|

|

Inogen One G2 |

|

||

|

Capacity (ml/min) |

|

630 |

|

|

1,050 |

|

|

|

1,260 |

|

|

Weight (lbs) |

|

2.8 (single battery) |

|

4.8 (single battery) |

|

|

7.0 (single battery) |

|

||

|

|

|

3.3 (double battery) |

|

5.8 (double battery) |

|

|

8.4 (double battery) |

|

||

|

Battery run-time |

|

Up to 2.6 hours (single battery) |

|

Up to 4.7 hours (single battery) |

|

|

Up to 5.0 hours (single battery) |

|

||

|

|

|

Up to 5 hours (double battery) |

|

Up to 10 hours (double battery) |

|

|

Up to 10.0 hours (double battery) |

|

||

|

Technology effective for |

|

|

|

|

|

|

|

|

|

|

|

overnight use |

|

Yes |

|

Yes |

|

|

Yes |

|

||

|

Sound |

|

40 dBA |

|

39 dBA |

|

|

≤ 38 dBA |

|

||

We have focused our research and development efforts on creating solutions that we believe have overcome the reputation of portable oxygen concentrators as being limited in durability and reliability as well as unsuitable for nighttime or 24/7 use. We specifically designed our compressors for 24/7 use.

All of our Inogen One systems are equipped with Intelligent Delivery Technology, a form of pulse-dose technology from which the patient receives a bolus of oxygen upon inhalation. Pulse-dose technology was developed to extend the number of hours an oxygen tank would last and is generally used on all ambulatory oxygen therapy devices. Our proprietary conserver technology utilizes differentiated triggering sensitivity to quickly detect a breath and ensure oxygen delivery within the first 400 milliseconds of inspiration, the interval when oxygen has the most effect on lung gas exchange. During periods of sleep, respiratory rates typically decrease. Our Inogen One systems actively respond to this changing physiology through the use of proprietary technology that increases bolus size. Our Intelligent Delivery Technology is designed to provide effective levels of blood oxygen saturation during sleep and all other periods of rest and activity that are substantially equivalent to continuous flow systems.

The Inogen One G4, our latest portable oxygen concentrator released to market in May 2016, is among the lightest products on the market and has higher oxygen production capabilities than the other sub-3 pound portable oxygen concentrators on the market. We believe the performance parameters around the Inogen One G4, Inogen One G3 and Inogen One G2 allow us to serve approximately 95% of the ambulatory oxygen patients and enable us to address a patient’s particular clinical needs, as well as lifestyle and performance preferences.

The Inogen At Home stationary oxygen concentrator allows us to access the non-ambulatory oxygen patient market and serves as a backup to our Inogen One system for ambulatory patients on our rental service. At approximately 18 pounds, we believe the Inogen At Home concentrator is the lightest five liter per minute continuous flow oxygen concentrator on the market today. Additionally, the Inogen At Home product has low power consumption with worldwide electrical compatibility, which should reduce the cost of electricity for oxygen therapy patients, as well as reduce manufacturing and distribution complexities. While the Inogen One product line is clinically validated for 24/7 use, the Inogen At Home represents a compelling solution for stationary oxygen therapy patients that do not require a portable solution, which are estimated to represent approximately 30% of total oxygen patients in the United States.

Our direct-to-consumer business model has enabled us to receive direct patient feedback, and we have used this feedback to create portable oxygen concentrators that address the full suite of features and benefits critical to patient preference and retention. Our products prevent patients from having to choose between lightweight size, suitability for 24/7 use, reliability, and key features such as battery life, flow and reduced noise levels.

Domestic sales and marketing

In the United States, we market and distribute our products directly to consumers, through a wide variety of direct-to-consumer sales and marketing strategies including consumer advertising, an inside-sales staff, and a physician referral model. Of the $193.9 million of our 2017 revenue derived from the United States, approximately 44.7% represented cash-pay sales to consumers, 43.0%

5

represented sales to traditional home medical equipment providers, distributors (including our private label partner) and resellers, and 12.3% represented direct-to-consumer rentals.

Our direct-to-consumer sales and marketing efforts are focused on generating awareness and demand for our Inogen One systems and Inogen At Home systems among patients, physicians and other clinicians, and third-party payors. As of December 31, 2017, we employed a marketing team of 8 people, an in-house sales team of 283 people (including 263 inside sales representatives), and a field-based sales team of 19 people (including 17 physician sales representatives).

Patients who choose to use their Medicare or private insurance benefits typically rent our systems. Those who purchase our product outright are typically patients who are not eligible to use their insurance benefits due to their capped rental status, prefer to own the equipment, or have an immediate need for our product that cannot be processed in time by their primary insurance carrier (e.g., an upcoming trip). Our ability to rent to Medicare patients directly, bill Medicare and other third-party payors on their behalf, and service patients in their homes requires that we hold a valid Medicare supplier number, are accredited by an independent agency approved by Medicare, and comply with the differing licensure and process requirements in the 49 states in which we serve patients.

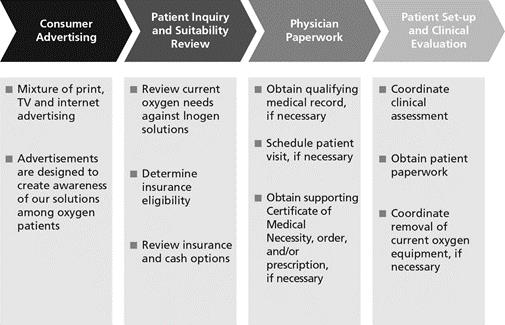

We use a variety of direct-to-consumer marketing strategies to generate interest in our solutions among current oxygen therapy patients. After a patient contacts us, we guide them through product selection and insurance eligibility, and, if they choose to move forward, process the necessary reimbursement and physician paperwork on their behalf, as well as coordinate the shipping, instruction, and clinical setup process. In accordance with Medicare regulations, we do not initially contact patients directly and contact them only upon an inbound inquiry or upon receipt of a physician’s order. The chart below describes our United States direct-to-consumer sales and rental process.

We engage in a number of other initiatives to increase awareness, demand, and orders for Inogen One systems and Inogen At Home systems. These include attendance at oxygen therapy support groups, guest speaking arrangements at trade shows, and product demonstrations, as requested. Additionally, we are targeting private payors to become an in-network provider of oxygen therapy solutions, which we expect will reduce patient co-insurance amounts associated with using our solution. We believe this will result in both increased conversion of our initial leads, as well as direct referrals from insurance companies in some cases.

To supplement the direct-to-consumer marketing model, we are also utilizing a physician referral model as a complementary sales method. Under this model, our field sales representatives work with physicians in the representative’s territory to help physicians understand our products and the value these products provide for patients. We believe that by educating physicians on our products, we can cost-effectively supplement our direct-to-consumer sales and rentals and capture a greater number of patients earlier in the course of their oxygen therapy.

6

Our direct-to-consumer marketing strategies also create demand for our products among other homecare equipment providers and business partners. In addition to generating consumer demand, we believe our products can create value for our business partners by either creating a retail sale opportunity for them or by reducing the need for costly home deliveries associated with oxygen tanks.

We sell to resellers and traditional homecare providers in the United States, Canada, Europe, the Asia-Pacific region, Latin America, the Middle East and Africa that choose to deploy our products to oxygen therapy patients. These customers market the benefits of our products to oxygen therapy patients through consumer advertising and/or retail locations or to physicians through field-based sales representatives. We believe that in addition to the marketing efforts employed by our business customers, our own direct-to-consumer marketing efforts in the United States result in patient interest that our business customers field.

We also sell to traditional homecare providers that offer our products to patients through insurance worldwide. Homecare providers that employ the standard delivery model with oxygen tanks need to replace the oxygen tanks on a regular basis by picking up the empty oxygen tanks and delivering full oxygen tanks for the patient. The delivery model has historically necessitated that a homecare provider have a facility near the oxygen patients that it serves and that the provider has invested in personnel, trucks, etc. to facilitate routine deliveries. The cost to deliver the oxygen tanks to patients is significant for many providers in the standard delivery model. Homecare providers that have adopted Inogen products have been able to reduce the costly deliveries associated with oxygen tanks since our products generate their own oxygen and don’t need to be refilled. Our business-to-business sales and marketing strategy for these customers is to raise awareness of our solutions and educate homecare providers on how our products may be able to reduce their total cost of ownership of servicing oxygen patients. As a homecare provider ourselves, we are able to help our business customers adopt a non-delivery oxygen therapy model utilizing patient preferred portable oxygen concentrators. We also private label our product with a business partner that sells to traditional homecare providers. Our private label partner employs field sales representatives that call on homecare providers to showcase the benefits of our products.

Concentration of Customers

We primarily sell our products to traditional home medical equipment providers, distributors, and resellers in the United States and in foreign countries on a credit basis. We also sell our products direct to consumers on a primarily prepayment basis. One single customer, Applied Home Healthcare Equipment, our private label distribution partner, represented more than 10% of our total revenue for 2017 and 2016, and no single customer represented more than 10% of our total revenue for 2015. Two customers with accounts receivable balances of $10.4 million and $6.5 million, respectively, each represented more than 10% of our net accounts receivable balance as of December 31, 2017, and one single customer with an accounts receivable balance of $9.8 million, represented more than 10% of our net accounts receivable balance as of December 31, 2016.

We also rent products directly to consumers for insurance reimbursement, which resulted in a customer concentration relating to Medicare’s service reimbursement programs. Medicare’s service reimbursement programs accounted for 73.0%, 72.6% and 73.7% of rental revenue in 2017, 2016 and 2015, respectively, and based on total revenue was 7.0%, 12.4% and 21.0% for 2017, 2016 and 2015, respectively. Net accounts receivable balances relating to Medicare’s service reimbursement programs (including held and unbilled receivables, net of allowances) amounted to $1.5 million or 4.8% of total net accounts receivable as of December 31, 2017 and $7.2 million or 23.4% of total net accounts receivable as of December 31, 2016.

International

Approximately 22.3% of our total revenue was from outside the United States in 2017. We sell through distributors, resellers, and home medical equipment providers in certain markets within Canada, Europe, the Asia-Pacific region, Latin America, the Middle East, and Africa. We sell our products in 45 countries outside the United States through distributors or directly to large “house” accounts, which include gas companies and home oxygen providers. In this case, we sell to and bill the distributor or house accounts directly, leaving the patient billing, support, and clinical setup to the local provider. As of December 31, 2017, we had 13 people located in the United States who focused on selling our products and providing service and support to distributors and house accounts worldwide and 11 employees located in Europe who provided sales, customer service, and repair services to a portion of our international customers. No single international customer and no single foreign country represented more than 10% of our total revenue in 2017, 2016 or 2015.

International sales revenue grew to $55.5 million in 2017 from $50.1 million in 2016. We estimate there are approximately more than 2 million long-term oxygen therapy patients outside of the United States. We believe that the international market is attractive for the following reasons:

|

|

• |

more favorable reimbursement in certain countries, including France and the United Kingdom, where portable oxygen concentrators receive more favorable reimbursement than in the United States. |

7

|

|

• |

an absence of reimbursement for any ambulatory oxygen therapy modalities in some countries, resulting in patients bearing all of the cost of ambulatory oxygen therapy and therefore becoming more involved in the selection of the modality. In Australia, for example, patients shoulder the burden of all costs associated with ambulatory oxygen therapy. In these cases, they tend to choose products like portable oxygen concentrators that provide a higher level of personal freedom. |

We will continue to focus on building out our international sales efforts. In 2017, we added a European customer support site in the Netherlands after acquiring a previous distributor, MedSupport, now operating under Inogen Europe B.V. The new site offers multi-lingual customer service, repair services, and basic distribution, to improve our European customer support at lower cost. Also in support of our European operations, we began production of our Inogen One G3 concentrator in the fourth quarter of 2017 using a contract manufacturer, Foxconn, located in the Czech Republic to improve our ability to service our European customers.

Customer support and order fulfillment

Our procedures enable us to package and ship a system directly to the patient in the patient’s preferred configuration the same day the order is received in most cases. This enables us to minimize the amount of finished goods inventory we keep on hand. Our primary logistics partner is United Parcel Service, or UPS. UPS supports our domestic shipments and provides additional services that support our direct-to-consumer oxygen therapy program. The UPS pick up service is used to retrieve products requiring repair and systems that are no longer needed by the patient. Additionally, UPS, when necessary and requested by us, will go into a patient’s home to remove a replacement product from the box, package the failed device and return it to us. In this manner, we are able to operate as a remote provider while maintaining the level of customer service of a local oxygen therapy provider. FedEx primarily supports our international shipments and limited domestic shipments.

We believe it is important to provide patients with quality customer support to achieve satisfaction with our products and optimal outcomes. As of December 31, 2017, we had a dedicated customer service team of 33 people who were trained on our products, a clinical support team of 25 people who were licensed nurses or respiratory therapists, and a dedicated billing services team of 78 people. We provide our patients with a dedicated 24/7 hotline. Via the hotline, patients have direct access to our customer service representatives, who can handle product-related questions. Additionally, clinical staff is on call 24/7 and available to patients whenever either the patient or the customer service representative deems appropriate. Our dedicated billing services team is available to answer patient questions regarding invoicing, reimbursement, and account status during normal business hours. We receive no additional reimbursement for patient support, but provide high-quality customer service to enhance patient comfort, satisfaction, compliance, and safety with our products.

Third-party reimbursement

Medicare and private insurance rentals represented approximately 9.6% of our total revenue in 2017, down significantly from 17.1% of our total revenue in 2016, primarily due to increased sales revenue with a continued focus on sales versus rentals and declines in reimbursement rates. In cases where we rent our oxygen therapy solutions directly to patients, we bill third-party payors, such as Medicare or private insurance, for monthly rentals on behalf of our patients. We process and coordinate all physician paperwork necessary for reimbursement of our solutions. A common medical criterion for oxygen therapy reimbursement is insufficient blood oxygen saturation level. Our team in sales and sales administration are trained on how to verify benefits, review medical records and process physician paperwork. Additionally, an independent internal review is performed and our products are not deployed until after physician paperwork is processed and reimbursement eligibility is verified and communicated to the patient.

We rely primarily on reimbursement from the Centers for Medicare and Medicaid Services (CMS), and secondarily, from private payors, Medicaid and patients for our rental revenue. For the year ended December 31, 2017, approximately 73.0% of our rental revenue was derived from Medicare’s service reimbursement programs. The U.S. list price for our stationary oxygen rentals (HCPCS E1390) is $260 per month and the U.S. list price for our oxygen generating portable equipment (OGPE) rentals (HCPCS E1392) is $70 per month. Effective January 1, 2016, the current standard Medicare allowable varies by state instead of the one national standard allowable as in previous years. The national standard allowable in 2015 for stationary oxygen rentals (E1390) was $180.92 per month and for OGPE rentals (E1392) was $51.63 per month. Effective January 1, 2016, the Medicare allowable for stationary oxygen rentals (E1390) ranges from $135.14 to $145.61 per month and the OGPE rentals (E1392) ranges from $46.69 to $49.52 per month. Effective January 1, 2017, the Medicare allowable for stationary oxygen rentals (E1390) ranges from $66.53 to $77.16 per month and the OGPE rentals (E1392) ranges from $36.14 to $41.91 per month. These are the two primary codes that we bill to Medicare and other payors for our oxygen product rentals.

8

As of January 1, 2011, Medicare phased in the competitive bidding program. The competitive bidding program impacts the amount Medicare reimburses suppliers of durable medical equipment rentals, including portable oxygen concentrators. The program is defined geographically, with suppliers submitting bids to provide medical equipment for specific product categories within a specified geographic region called competitive bidding areas, or CBAs. Once bids have been placed, an individual company’s bids within a product category are aggregated and weighted by each product’s market share in the category. The weighted-average price is then indexed against all bidding suppliers. Medicare determines a “clearing price” out of these weighted-average prices, at which a sufficient number of suppliers have indicated they will support patients in the category. This threshold is typically designed to generate theoretical supply that is twice the expected demand. Bids for each modality among the suppliers that made the cut are then arrayed to determine what Medicare will reimburse for each product category and geographic area. The program has strict anti-collusion guidelines to ensure bidding is truly competitive. A competitive bidding contract lasts up to three years once implemented, after which the contract is subject to a new round of bidding. Discounts off the standard Medicare allowable occur in CBAs where contracts have been awarded as well as in cases where private payors pay less than this allowable. Competitive bidding rates are based on the zip code where the patient resides. Rental revenue includes payments for product, disposables, and customer service/support.

In the CBAs covered under round two re-compete of the competitive bidding program, which began July 1, 2016, the Medicare allowable for stationary oxygen rentals (E1390) ranges from $70.00 to $89.86 per month (average of $76.84 per month) and the OGPE rentals (E1392) ranges from $33.97 to $42.00 per month (average of $37.90 per month). In the CBAs covered under round one 2017 of the competitive bidding program, which began January 1, 2017, the Medicare allowable for stationary oxygen rentals (E1390) ranges from $70.04 to $90.01 per month (average of $77.97 per month) and the OGPE rentals (E1392) ranges from $35.11 to $37.15 per month (average of $36.06 per month).

As of January 1, 2016, all areas previously not subject to competitive bidding program (non-competitive bidding areas or “non-CBAs”) have experienced reductions in the Medicare fee schedule for durable medical equipment, prosthetics, orthotics and supplies (DMEPOS). The fee schedules in the non-CBAs were adjusted based on regional averages of the single payment amounts that apply to the competitive bidding program (Adjusted Fee Schedule). The regional prices are limited by a national ceiling (110% of the average of the regional prices) and a national floor (90% of the average regional prices). From January 1, 2016 to June 30, 2016, the reimbursement rates for these non-CBAs (with dates of service from January 1, 2016 to June 30, 2016) were 50% of the un-adjusted fee schedule amount plus 50% of the Adjusted Fee Schedule amount. As of July 1, 2016, Medicare reimbursed DMEPOS at 100% of the Adjusted Fee Schedule amount. However, in December 2016, the 21st Century Cures Act (“Cures Act”) was passed, which included a provision to roll-back the second cut to the non-CBA areas that was effective July 1, 2016 through December 31, 2016. Pricing in these areas was increased to the rates experienced in the period from January 1, 2016 through June 30, 2016. This led to a benefit in rental revenue of $2.0 million in the fourth quarter of 2016 and $0.2 million in the first quarter of 2017. Effective January 1, 2017, rates are set at 100% of the Adjusted Fee Schedule amount, based on the regional competitive bidding rates. The Cures Act also calls for a study of the impact of the competitive bidding pricing on rural areas and accelerated the implementation of the Omnibus bill passed in December 2015 that will require state Medicaid agencies to match Medicare fee schedule reimbursement rates (including single payment amounts in applicable areas) to be effective beginning January 1, 2018, including for oxygen.

The competitive bidding regions are defined as follows:

|

Region Name |

|

States Covered |

|

Far West |

|

CA, NV, OR, WA |

|

Great Lakes |

|

IL, IN, MI, OH, WI |

|

Mideast |

|

DC, DE, MD, NJ, NY, PA |

|

New England |

|

CT, MA, NH, RI |

|

Plains |

|

IA, KS, MN, MO, NE |

|

Rocky Mountain |

|

CO, ID, UT |

|

Southeast |

|

AL, AR, FL, GA, KY, LA, NC, SC, TN, VA |

|

Southwest |

|

AZ, NM, OK, TX |

9

In addition to regional pricing, CMS imposed different pricing on “frontier states” and rural areas. CMS defines frontier states as states where more than 50% of the counties in the state have a population density of 6 people or less per square mile and rural states are defined as states where more than 50% of the population lives in rural areas per census data. Current frontier states include MT, ND, SD and WY; rural states include ME, MS, VT and WV; and non-contiguous United States areas include AK, HI, Guam and Puerto Rico. For frontier and rural states, and frontier and rural zip codes in non-frontier/rural states, the single payment amount will be the national ceiling (110% of the average of the regional prices) to account for higher servicing costs in these areas. For non-contiguous United States areas, single payment amounts will be the higher of the national ceiling, or the average of competitive bidding pricing from these areas, if the areas had been bid through competitive bidding. We estimate that less than 10% of our patients would be eligible to receive the 110% of the regional prices for rural and frontier areas based on the geographic locations of our current patient population.

CMS has also re-bid for competitive bidding round two re-compete, which is associated with approximately 50% of the Medicare market, with contracts which began on July 1, 2016 and will continue through December 31, 2018. CMS updated the product categories and the competitive bidding areas in the round two re-compete contracts. Respiratory equipment now includes oxygen, oxygen equipment, continuous positive airway pressure devices, respiratory assist devices and related supplies and accessories. Nebulizers are now their own separate product category instead of being included in the respiratory equipment category. Round two re-compete is in the same geographic areas that were included in the original round two. However, as a result of the Office of Management and Budget’s updates to the original 91 round two metropolitan statistical areas, there are now 90 metropolitan statistical areas for round two re-compete and 117 competitive bidding areas (CBAs). Any CBA that was previously located in multi-state metropolitan statistical areas was redefined so that no CBA is included in more than one state. The round two re-compete competitive bidding areas have nearly the same zip codes as the round two competitive bidding areas; the associated changes in the zip codes since competitive bidding was implemented are reflective in this round two re-compete.

CMS has also re-bid for the round one 2017 contracts effective January 1, 2017 through December 31, 2018. In round one 2017, there are 9 metropolitan statistical areas and 13 CBAs to ensure there are no multi-state CBAs. We estimate approximately 9% of the Medicare market was impacted by the round one 2017 contracts.

The following table sets forth the current Medicare standard allowable reimbursement rates and the average of reimbursement rates applicable in Metropolitan Statistical Areas covered by rounds one and two of competitive bidding.

|

|

|

|

|

|

|

Round one |

|

|

Round two |

|

|

Round one |

|

|||

|

|

|

Round two |

|

|

re-compete |

|

|

re-compete |

|

|

2017 |

|

||||

|

|

|

average |

|

|

average |

|

|

average |

|

|

average |

|

||||

|

|

|

7/1/13- |

|

|

1/1/14- |

|

|

7/1/16- |

|

|

1/1/17- |

|

||||

|

|

|

6/30/16 |

|

|

12/31/16 |

|

|

12/31/18 |

|

|

12/31/18 |

|

||||

|

E1390 (stationary oxygen rentals) |

|

$ |

93.07 |

|

|

$ |

95.74 |

|

|

$ |

76.84 |

|

|

$ |

77.97 |

|

|

E1392 (portable oxygen rentals) |

|

|

42.72 |

|

|

|

38.08 |

|

|

|

37.90 |

|

|

|

36.06 |

|

|

Total |

|

$ |

135.79 |

|

|

$ |

133.82 |

|

|

$ |

114.74 |

|

|

$ |

114.03 |

|

In addition to reducing the Medicare reimbursement rates in the Metropolitan Statistical Areas (MSAs), the competitive bidding program has effectively reduced the number of oxygen suppliers that can participate in the Medicare program. Based on industry data analyzing the number of unique supplier companies by state from July 2013 to April 2017, there has been a 41% decrease in the numbers of DMEPOS suppliers who have an active NPI number. We believe that approximately 59% of the Medicare market was covered by round one and round two of competitive bidding.

Cumulatively in round one, round two, round one re-compete, round two re-compete and round one 2017, we were offered contracts for a substantial majority of the CBAs and product categories for which we submitted bids. However, there is no guarantee that we will garner additional market share as a result of these contracts. The contracts include products that may require us to subcontract certain services or products to third parties, which must be approved by CMS. We currently operate in 49 of the 50 states in the U.S. We do not operate in Hawaii due to the licensure requirements.

Moreover, we cannot guarantee that we will be offered contracts in subsequent rounds of competitive bidding. In all five rounds of competitive bidding in which we have participated, we have gained access to certain CBAs and been excluded from other CBAs.

Following round one of competitive bidding, we were excluded from providing services to Medicare beneficiaries in the Kansas City-MO-KS, Miami-Fort Lauderdale-Pompano Beach-FL, and Orlando-Kissimmee-FL CBAs. We had access to six CBAs of the nine regions subject to competitive bidding round one for the respiratory product category.

10

After round one re-compete of competitive bidding, we were excluded from providing services to Medicare beneficiaries in the following CBAs: Cleveland-Elyria-Mentor-OH, Cincinnati-Middleton-OH-KY-IN, Miami-Fort Lauderdale-Pompano Beach-FL, Orlando-Kissimmee-Sanford-FL, Pittsburg-PA, and Riverside-San Bernardino-Ontario-CA. We gained access to the Kansas City-MO -KS CBA. We had access to three CBAs of the nine regions subject to competitive bidding round one re-compete for the respiratory product category.

After round one 2017 of competitive bidding, we have been excluded from the Chester-Lancaster and York Counties-SC CBA, which we previously won under round one re-compete. We also have been excluded from the Miami-Fort Lauderdale-West Palm Beach-FL and Orlando-Kissimmee-Sanford-FL CBAs. We have access to 10 of the 13 CBAs in which we bid for the respiratory product category: Charlotte-Concord-Gastonia-NC, Cincinnati-OH, Cleveland-Elyria-OH, Covington-Florence-Newport-KY, Dallas-Fort Worth-Arlington-TX, Dearborn-Franklin-Ohio, and Union Counties-IN, Kansas City-MO, Kansas City-Overland Park-Ottawa-KS, Pittsburgh-PA, and Riverside-San Bernardino-Ontario-CA. We have access to ten CBAs of the thirteen regions subject to competitive bidding round one 2017 for the respiratory product category.

After round two of competitive bidding, we were excluded from 12 CBAs: Akron-OH, Cape Coral-Fort Myers-FL, Deltona-Daytona Beach-Ormond Beach-FL, Honolulu-HI, Jacksonville-FL, Lakeland-Winter Haven-FL, Memphis-TN-MS-AR, North Port-Bradenton-Sarasota-FL, Ocala-FL, Palm Bay-Melbourne-Titusville-FL, Tampa-St. Petersburg-Clearwater-FL, and Toledo-OH. We had access to 88 CBAs of the 100 regions subject to competitive bidding round two for the respiratory product category.

After round two re-compete of competitive bidding, we were excluded from the following CBAs that we had previously won under round two: Allentown-Bethlehem-Easton-PA, Asheville-NC, Augusta-Richmond County-GA, Camden-NJ, Catoosa-Dade-Walker Counties-GA, Elizabeth-Lakewood-New Brunswick-NJ, Flint-MI, Greensboro-High Point-NC, Greenville-Anderson-Mauldin-SC, Jersey City-Newark-NJ, Las Vegas-Henderson-Paradise-NV, Little Rock-North Little Rock-Conway-AR, Louisville-Jefferson County-KY, Mercer County-PA, Poughkeepsie-Newburgh-Middletown-NY, Raleigh-NC, Scranton-Wilkes-Barre-Hazelton-PA, Stockton-Lodi-CA, Syracuse-NY, Wilmington-DE, and Youngstown-Warren-Boardman-OH. We were also excluded from the following CBAs in both round two and round two re-compete: Akron-OH and Toledo-OH. We gained access to certain Medicare markets in Cape-Coral-Fort Myers-FL, Deltona-Daytona Beach-Ormond Beach-FL, Jacksonville-FL, Lakeland-Winter Haven-FL, North Port-Sarasota-Bradenton-FL, Ocala-FL, Palm Bay-Melbourne-Titusville-FL, and Tampa-St. Petersburg-Clearwater-FL. We have access to 93 CBAs of the 117 regions subject to competitive bidding round two re-compete for the respiratory product category.

Effective January 1, 2017, we believe we have access to over 85% of the Medicare oxygen therapy market based on our analysis of the 103 CBAs that we have won out of the 130 total CBAs. These 130 CBAs represent approximately 59% of the market with the remaining approximately 41% of the market not subject to competitive bidding. The loss of access to the CBAs where we were not awarded contracts is not expected to lead to a material adverse impact on our rental business. Medicare revenue, including patient co-insurance and deductible obligations, represented 7.0% of our total revenue in the year ended December 31, 2017. We expect the decline in total revenue resulting from the loss of competitive bidding contracts in the areas that we were excluded from to be partially offset by the “grandfathering” of existing Medicare patients (discussed below), rentals to patients with third-party insurance coverage, or Medicare patients paying out-of-pocket to purchase our products. Our revenue from Medicare in the 27 CBAs where we were not offered contracts as of January 1, 2017 was approximately $0.8 million and $1.8 million in the years ended December 31, 2017 and 2016, respectively.

Under the competitive bidding program, DME suppliers that are not awarded a competitive bid contract in a CBA and product category which the DME supplier had previously been awarded a competitive bid contract may “grandfather” existing patients on service beginning on the effective date of the competitive bidding round. This means DME suppliers may retain all existing patients and continue to receive reimbursement for them, so long as the new reimbursement rate is accepted by the DME supplier and the beneficiary chooses to continue to receive equipment from the supplier. For example, a supplier that received a round two contract but not a round two re-compete contract may elect to “grandfather’ the patients that it serviced through the round two contract period. Suppliers must either keep or release all patients under this “grandfathering” arrangement in each CBA; a supplier may not select specific individuals to retain or release. Suppliers can continue to sell equipment in CBAs where they were not awarded contracts to patients paying out-of-pocket or with third-party insurance coverage.

We have elected to “grandfather” and retain all patients in CBAs in which we were not awarded contracts. In addition, we continue to accept patients in CBAs where we did not receive contracts through private insurance. We also pursue retail sales of our equipment to patients in those areas.

Medicare reimbursement for oxygen rental equipment is limited to a maximum of 36 months within a 60-month service period, and the equipment remains the property of the home oxygen supplier. The supplier that billed Medicare for the 36th month of service continues to be responsible for the patient’s oxygen therapy needs for months 37 through 60, and there is generally no additional reimbursement for oxygen generating portable equipment for these later months. CMS does not separately reimburse suppliers for

11

oxygen tubing, cannulas and supplies that may be required for the patient. The supplier is required to keep the equipment provided in working order and in some cases, CMS will reimburse for repair costs. At the end of the five-year useful life of the equipment, the patient may request replacement equipment and, if he or she can be re-qualified for the Medicare benefit, a new maximum 36-month payment cycle out of the next 60 months of service would begin. The supplier may not arbitrarily issue new equipment. We have analyzed the potential impact to revenue associated with patients in the capped rental period and have deferred $0 associated with the capped rental period as of December 31, 2017 and December 31, 2016.

Our obligations to service Medicare patients over the contract rental period include supplying working equipment that meets each patient’s oxygen needs pursuant to his/her doctor’s prescription and certificate of medical necessity form and supplying all disposables required for the patient to operate the equipment, including cannulas, filters, replacement batteries, carts and carry bags, as needed. If the equipment malfunctions, we must repair or replace the equipment. We determine what equipment the patient receives, as long as that equipment meets the physician’s prescription, and we can deploy used assets in working order as long as the prescription requirements are met. We must also procure a recertification of the certificate of medical necessity from the patient’s doctor to confirm the patient’s need for oxygen therapy one year after the patient first receives oxygen therapy and one year after each new 36-month reimbursement period begins. The patient can choose to receive oxygen supplies and services from another supplier at any time, but the supplier may only transition the patient to another supplier in certain circumstances.

In addition to the adoption of the competitive bidding program, from 2010 through 2015, Medicare reimbursement rates for oxygen rental services in non-CBAs were eligible to receive mandatory annual updates based upon the Consumer Price Index for all Urban Consumers, or CPI-U. For 2014, the CPI-U was +1.8%, but the multi-factor productivity adjustment (Adjustment) was -0.8%, so the net result was a 1.0% increase in fee schedule payments in 2014 for items and services provided in areas not subject to competitive bidding. However, by law, the stationary oxygen equipment codes payment amounts must be adjusted on an annual basis, as necessary, to ensure budget neutrality of the new payment class for oxygen generating portable equipment (OGPE). Thus, the increase in allowable payment amounts for stationary oxygen equipment codes increased 0.5% from 2013 to 2014. For 2015, the CPI-U was +2.1%, but the Adjustment was -0.6%, so the net result was a 1.5% increase in fee schedule payments in 2015 for stationary oxygen equipment for items and services not included in an area subject to competitive bidding. Beginning in 2016, the standard allowable for all areas was set based on regional averages of the competitive bidding prices as described previously and no fees were based on non-competitive bidding. Accordingly, we do not anticipate future adjustments to the reimbursable fees based upon changes in CPI-U. However, as of January 1, 2017 and January 1, 2018 the Medicare reimbursement rates in the non-CBAs were adjusted to ensure budget neutrality based on the increased usage of the OGPE class that led to lower rates in these areas.

On November 4, 2016, CMS published a final rule in the Federal Register imposing additional regulations on the competitive bidding process. The final rule requires bidders choosing to participate in the competitive bidding program to obtain a $0.05 million surety bond for each CBA in which they bid. If a bidder does not accept a contract offer when its composite bid is at or below the median composite bid rate for suppliers used in the calculation of the single payment amount, the bid surety bond for the applicable CBA will be forfeited to CMS. In instances where the bidder does not meet the forfeiture conditions specified in the final rule, the bid surety bond liability will be returned to the bidder within 90 days of the public announcement of the contract suppliers for the CBA. Currently, there are 130 CBAs, which would mean a bidding supplier could incur a surety bond obligation with forfeiture conditions of up to $6.5 million. The final rule also changes the bid limits for individual items for future rounds of competitive bidding to reflect the 2015 unadjusted fee schedule to avoid a downward trend in bid pricing, to ensure the long-term viability of the competitive bidding program, and to allow suppliers to take into account both decreases and increases in costs in determining their bids. The rule also finalizes an appeals process for all breach of contract actions that CMS may take under the competitive bidding program. Lastly, the final rule sets forth a provision for lead item bidding for certain product categories in future bidding rounds to prevent the creation of price inversions, which occurred in round two of competitive bidding. Lead item bidding means that all HCPCS codes for similar items will be grouped together and priced relative to the bid for the “lead item,” as calculated by CMS.

On November 2, 2017, a bi-partisan bill with 122 co-sponsors was introduced in the House of Representatives that would provide relief from competitive bidding in non-bid areas. If passed, the bill would extend a retroactive delay of a second round of reimbursement cuts for Medicare beneficiaries from January 1, 2017 to January 1, 2019 based on the reimbursement rates effective on January 1, 2016. The legislation also proposes to remedy a double-dip cut to oxygen payments caused by the misapplication of a 2006 budget neutrality offset balancing increased utilization for oxygen generating portable equipment with lower reimbursement for stationary equipment.

On February 12, 2018, the current presidential administration sent Congress a 2019 budget proposal that included language on competitive bidding. Specifically, the proposal eliminates the requirement under the competitive bidding program that CMS pay a single payment amount based on the median bid price, instead paying winning suppliers at their own bid amounts. Additionally, this proposal expands competitive bidding to all areas of the country, including rural areas, which will be based on competition in those areas rather than on competition in urban areas. This specific proposal is estimated to save the government $6.5 billion over 10 years. In addition to changes to competitive bidding, the 2019 budget proposal would enable CMS not to impose the face-to-face

12

requirement on all providers for durable medical equipment. Furthermore, the proposal seeks to address excessive billing of durable medical equipment that requires refills or serial claims. Specifically, Medicare would gain authority to test whether using a benefits manager for serial durable medical equipment claims result in lower improper payments and reductions in inappropriate utilization. The benefits manager would be responsible for ensuring beneficiaries were receiving the correct quantity of supplies or service for the appropriate time period. Lastly, the proposal would expand prior authorization to additional items and services that are both high-cost and at high-risk for improper payments.

As of December 31, 2017, we had 93 contracts with Medicaid and private payors. These contracts qualify us as an in-network provider for these payors. As a result, patients can rent or purchase our systems at the same patient obligation as other in-network oxygen suppliers. Based on our patient population, we believe at least 30% of all oxygen therapy patients are covered by private payors. Private payors typically provide reimbursement at a rate between 60% and 100% of Medicare allowables for in-network plans, and although private payor plans can have 36-month capped rental periods similar to Medicare, they typically do not. We anticipate that private payor reimbursement levels will generally be reset in accordance with Medicare payment amounts established through competitive bidding.

We cannot predict the full extent to which reimbursement for our products will be affected by competitive bidding, the 2017 federal budget or future federal budgets, or by initiatives to reduce costs for private payors. We believe that we are well positioned to respond to the changing reimbursement environment because our product offerings are innovative, patient-focused and cost-effective. We have historically been able to reduce our costs through scalable manufacturing, better sourcing, continuous innovation, and reliability improvements, as well as innovations that reduce our product service costs by minimizing exchanges, such as user replaceable batteries. As a result of design changes, supplier negotiations, bringing manufacturing and assembly largely in-house and our commitment to driving efficient manufacturing processes, we have reduced our overall system cost 58% from 2009 to 2017. We intend to continue to seek ways to reduce our cost of revenue through manufacturing and design improvements.

For additional discussion of the impact of the recent competitive bidding proposals, see “Risk Factors” herein.

Manufacturing and raw materials

We have been developing and refining the manufacturing of our Inogen One systems since 2004. While nearly all of our manufacturing and assembly processes were originally outsourced, assembly of the compressor, sieve bed, concentrator and certain manifolds is now conducted in-house in order to improve quality control and reduce cost. Additionally, we use lean manufacturing practices to maximize manufacturing efficiency. We rely on third-party manufacturers to supply several components of our Inogen One and Inogen At Home systems. We typically enter into supply agreements for these components that specify quantity and quality requirements and delivery terms. In certain cases, these agreements can be terminated by either party upon relatively short notice but in other instances we are obligated to purchase minimum quantities. We have elected to source certain key components from single sources of supply, including our batteries, motors, valves, and some molded plastic components. We believe that maintaining a single source of supply allows us to control production costs and inventory levels and to manage component quality. In order to mitigate against the risks related to a single source of supply, we qualify alternative suppliers and develop contingency plans for responding to disruptions. However, any reduction or halt in supply from one of these single-source suppliers could limit our ability to manufacture our products or devices until a replacement supplier is found and qualified.

We currently manufacture in two leased buildings in Goleta, California and Richardson, Texas, that we have registered with the Food and Drug Administration, or FDA, and for which we have obtained International Standards Organization, or ISO, 13485 certification. We plan to continue the expansion of our facilities located in Richardson, Texas. We also began production of our Inogen One G3 concentrators in the fourth quarter of 2017 using a contract manufacturer, Foxconn, located in the Czech Republic to improve our ability to service our European customers. We believe we and our manufacturing partner have sufficient capacity to meet anticipated demand.

Our entire organization is responsible for quality management. Our Quality Assurance department oversees this by tracking component, device and organization performance and by training team members outside the Quality Assurance department to become competent users of our Quality Management system. By measuring component performance, communicating daily with the production group and our suppliers, and reviewing customer complaints, our Quality Assurance department, through the use of our corrective action program, drives and documents continuous performance improvement of our suppliers and internal departments. Our Quality Assurance department also trains internal quality auditors to audit our adherence to the Quality Management system. Our Quality Management system has been certified to ISO 13485:2012 by BSI, a Notified Body to ISO.

Our manufacturing partner is expected to ramp capacity in 2018 to produce Inogen One G3 concentrators required to support our European demand. We expect to maintain our assembly operations for our Inogen One concentrators and Inogen At Home concentrators at our facility in Richardson, Texas and will continue to assemble compressors and sieve bed columns at our facility in

13

Goleta, California. This will allow us to expand our manufacturing capacity and redirect our U.S. manufacturing activities to focus on growth in the U.S. and on our latest product, the Inogen One G4.